In the world of food preservation, the battle between maintaining freshness and extending shelf life is fought with the help of specialized equipment. Discover the nuances and unique purposes of blast chillers, blast freezers, and shock freezers as we dive into the realm of rapid temperature control.

When it comes to the rapid cooling or freezing of food, the terms “blast chiller,” “blast freezer,” and “shock freezer” are often used interchangeably, leading to confusion. However, these appliances have distinct characteristics, temperature ranges, and applications that set them apart.

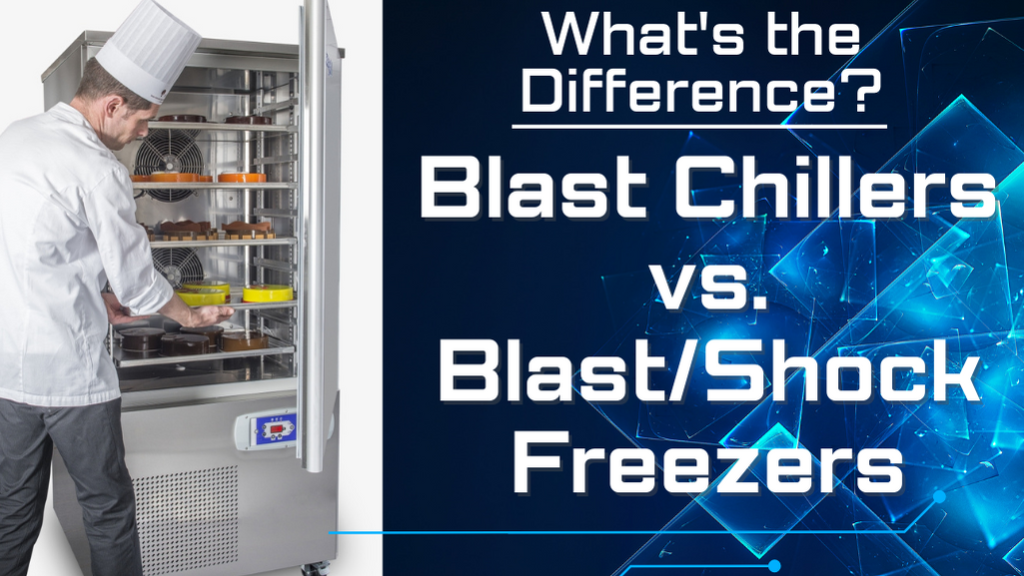

Blast Chiller:

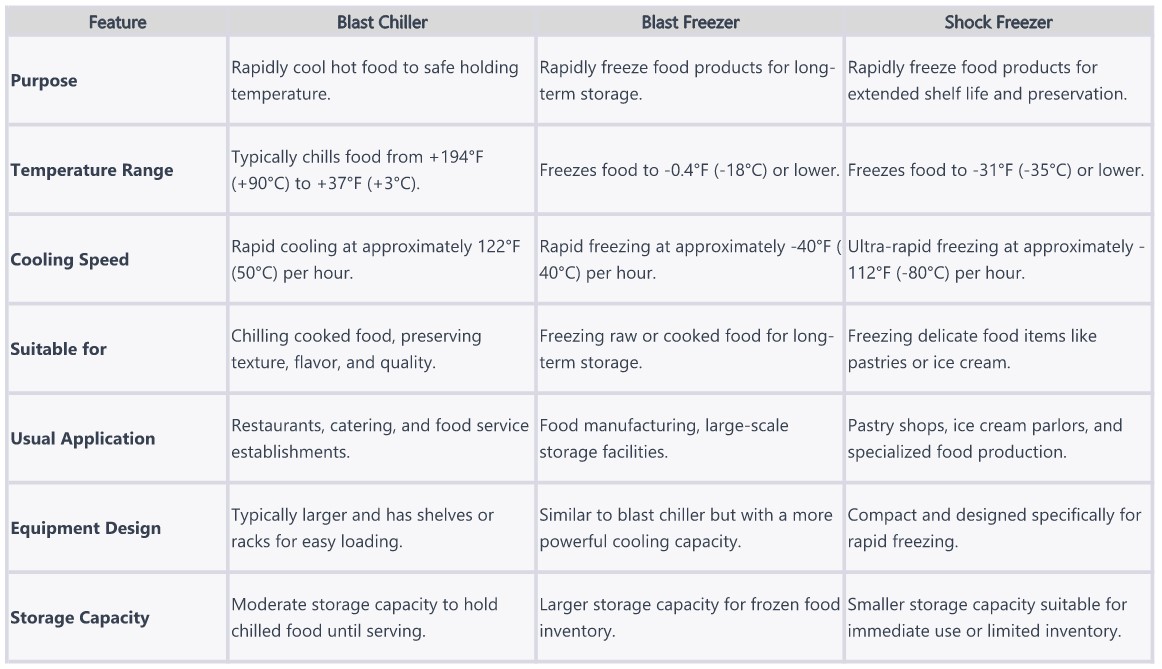

Let’s begin with the blast chiller—a culinary lifesaver in restaurants, catering services, and various food establishments. Designed to cool hot food rapidly to a safe holding temperature, blast chillers preserve the texture, flavor, and quality of cooked dishes. Operating within a temperature range of around +194°F (+90°C) to +37°F (+3°C), they employ a powerful cooling process that can lower food temperatures at approximately 122°F (50°C) per hour. Blast chillers are ideal for ensuring food safety while maintaining freshness, making them indispensable in busy kitchens.

Blast Freezer:

On the other end of the spectrum, we have blast freezers, which specialize in freezing food products for long-term storage. These appliances take the chilling game to sub-zero levels, typically reaching -0.4°F (-18°C) or lower. With their robust cooling capacity, blast freezers can freeze raw or cooked food at an impressive rate of approximately -40°F (-40°C) per hour. Often found in food manufacturing facilities and large-scale storage facilities, blast freezers offer expansive storage capacities to accommodate frozen food inventories. They are instrumental in maintaining food quality and extending shelf life, allowing businesses to efficiently manage their supply chains and stock up on products for extended periods.

Shock Freezer:

Now, let’s shift our focus to the crème de la crème of rapid freezing—the shock freezer. This specialized equipment is the go-to choice for delicate food items like pastries or ice cream. Shock freezers take freezing to the extreme, boasting ultra-rapid cooling capabilities that can reach temperatures as low as -31°F (-35°C) or even lower, sometimes touching -112°F (-80°C) per hour. Shock freezers are compact in design, with smaller storage capacities compared to blast freezers. They are tailored for immediate use or limited inventory, allowing pastry shops, ice cream parlors, and specialized food production facilities to freeze delicate creations quickly without compromising their texture or taste.

Conclusion:

To summarize, blast chillers, blast freezers, and shock freezers each play a vital role in the realm of rapid temperature control. Blast chillers excel at swiftly cooling hot food for safe storage, blast freezers freeze food for long-term preservation and efficient inventory management, while shock freezers provide ultra-rapid freezing to safeguard the delicate nature of certain food items. Understanding these differences will help businesses choose the most suitable equipment to meet their specific needs, ensuring optimal food quality, safety, and longevity.

So, whether you’re in need of a culinary savior to preserve your hot dishes, a freezing wizard to stock your inventory, or an icy magician to protect your delicate creations, these specialized appliances are here to take the temperature control game to new levels, ensuring that freshness and longevity go hand in hand in the world of food preservation.

At the PES Design Group our mission is: “Designing functionally innovative, attractive and profitable c-store and food service facilities on time and on budget”. Our promise to you is, that whatever your project may be, we will approach it as unique. We will use our years of experience to design innovation and uniqueness into your project helping you to set yourself apart from the rest. We will also use innovation to solve challenging issues such as space, time and budget constraints.

About the Consultant

Jim Richards (Jr) is President of and Food Service Consultant with PES Design Group. During his 30+ years of experience in the Food Service Design Industry, Jim has encountered countless design challenges that he has successfully overcome through experience, innovation and a wealth of knowledge about efficient kitchen design and foodservice equipment.

Call us today for a FREE consultation about your project! 800.850.6638